For a while now we've been working on something very exciting and finally it's time to share it with you...

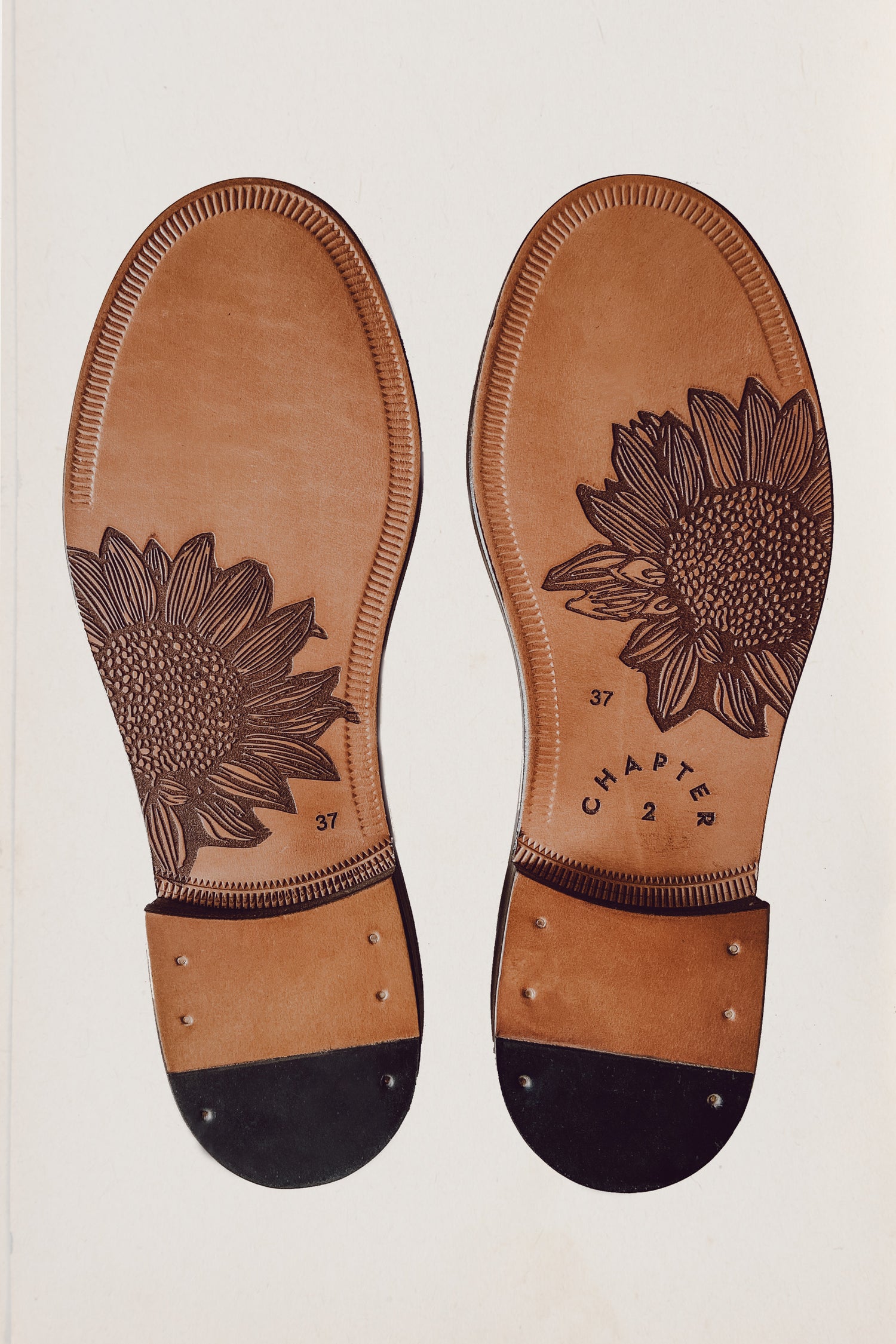

When we started Chapter 2 we wanted to create the most beautiful shoes that we could. Something extra special and that meant no compromise. Our classic foundation with it's touch of attitude, combined with the most beautiful materials, leather sole, quality hand craftsmanship and luxury packaging. Going forwards our beautiful hand crafted shoes will form a DELUXE range: exclusive made to order styles where we push our unique creativity using the most luxury materials, but that's nothing new, right?

The exciting part is that alongside that we've created a new range which is more competitive in price and more accessible to those of you who have our shoes or boots on your wish lists. The style that you love from us won't change as we've re-worked our most favourite and iconic styles but the price will be approx 1/3 less than normal, with shoes starting under £100. The other exciting thing about our new collection is that we will be carrying a small stock of sizes. While our deluxe hand made shoes will remain exclusively made to order, this new collection will be ready and available. To achieve this we've made a few changes: different leathers, rubber sole and although the shoes will still be made in our own workshop not long ago we invested in a machine to help us make the shoes that little bit quicker and easier.

To explain: originally our plan was to make this new collection at a small factory in Spain, but having developed several samples unfortunately the factory we were working with closed overnight and we were forced to find another way. If we couldn't get someone to make our new collection we'd just have to make them ourselves. So we invested in machinery. To be honest with you it's the most expensive thing that we've ever bought by some distance. So, what does it do? The machine in question is a back part moulder and it's role is to speed up part of the making process. For those of you who aren't shoe folk the machine moulds the heel area including the internal stiffner which gives the heel it's shape and structure. By hand this process takes over half an hour if you're working at speed and to do this with the machine takes 3-5 mins and is much more consistent. Aside from that all you need to know is that Tom (the shoemaker) is very happy with his new toy and is super busy making shoes and boots :)

The workshop is currently full steam ahead finishing everything ready to launch. Not long now... check out our AW17 look book "for we too are gypsies" for a preview of the good things to come..